- +91 99247 33111

- inquiry@vhptsystem.com

Post-tensioning is a method of reinforcing concrete or other construction materials with high-strength steel strands/wires/cables generally known as tendons, applications include office and apartment buildings, parking structures, slabs-on-ground, bridges, sports stadiums, rock and soil anchors, and water-tanks. The advantages of post-tensioning brings to a structure include large span, column free floor spaces and also reduces the amount of conventional reinforcement and concrete required thus delivering a more adoptable and environmentally friendly solution.

Post-tensioning is a method of reinforcing concrete or other construction materials with high-strength steel strands/wires/cables generally known as tendons, applications include office and apartment buildings, parking structures, slabs-on-ground, bridges, sports stadiums, rock and soil anchors, and water-tanks. The advantages of post-tensioning brings to a structure include large span, column free floor spaces and also reduces the amount of conventional reinforcement and concrete required thus delivering a more adoptable and environmentally friendly solution.

In 1872, P.H.Jackson (Billington, 2004), a Northern California Engineer, obtained a patent for post-tensioning.

In 1888 by C.W.doehring, who obtained a patent in Germany for pre-stressing slabs with metal wires/cables.

In 1940 Egene freyssinet introduced the system comprised of conical wedge anchors for 12 wire tendons.

In 1950s the post-tensioning is introduced in building structures in India.

In 1963, by T.Y.Lin come up with the load balancing which is a basics form of load balancing allows the engineer to view the effects of post-tensioning as a reduction in the desigh dead load applied to slab. As explained below

Post-tensioning is the slab reinforcement process of choice for slab-on-ground, elevated slab applications and many more. This engineered solution creates cast-in-place, pre-stressed concrete by reinforcing the foundation after the concrete has been placed.

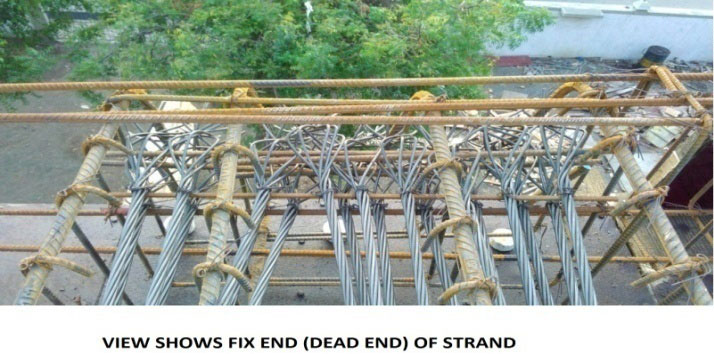

In post-tension construction, tendons are placed prior to concrete placement, and once the concrete reaches a specific initial compressive strength, the tendons are stressed to a specified force and anchored.

Post-Tensioning enhances concrete strength under both compressive and tensile stresses.

Post-tensioning external compressive force makes the concrete more resistant to the tensile stresses that would otherwise cause a foundation to pull apart and crack.

| Floor System | Span Range |

|---|---|

| Flate Plate | 7-10 MTR |

| Flat Slab With Drops | 8-12 MTR |

| Beam Slab | 8-16 MTR |

| Beam Waffle Slab | 10-20 MTR |

What sets VHPT Post-Tension apart from other PT specialists are our breadth and scope of services, our commitment to excellence, and our strong, national presence.

VHPT Post-Tension is:

Our Safety Commitment:

Experience the VHPT Post-Tension Difference:

Two-way post tensioning flat slabs dispense with the requirement for drop beams, providing enhanced flexibility for space partitioning and for the placing of service networks. (HVAC, electrical, sanitary etc..)

The simple concept of post tensioned slabs has a reduced amount of ordinary reinforcement and flexibility in the positioning of openings and inserts for services.

Little coordination is required between designers for this purpose, and late modifications can be implemented without detriment to the initial structural and architectural design.

The concerns about the demolition or alterations of post tensioned slabs have been dispelled in recent years. Knockout zones can be easily identified for future service penetrations. Tried and tested methods are available to enable large openings to be formed subsequently in as built slab conditions, particularly for bonded slabs.

Due to minimal need for drop beams and the reduced slab thickness, minimum storey height is achieved, leading to a lower overall building height.

In situations where the height of the building is limited, the reduced storey height can allow for additional floors to be constructed within the building envelope. The reduced façade area, as well as the vertical runs of mechanical and electrical systems sees cost benefits.

Post tensioned floors being in compression, allow for easier control of cracking. If appropriate design criteria are applied, crack-free construction can be achieved. This is often exploited in car parks with concrete surfaces exposed to an aggressive environment. With reduced cracking and better water tightened the durability of the structure is improved.

Bonded post-tensioned concrete is a method of applying compression after pouring concrete and during the curing process (in situ). The concrete is cast around a plastic/steel/aluminum circular/flat duct. A group of tendons/wires/cables are fished through the duct circular/flat and the concrete is poured, Once the concrete has hardened, the tendons are tensioned by hydraulic jacks that react (push) against the concrete member itself. When the tendons have stressed sufficiently, according to the design specifications, they are wedged in position and maintain tension after the jacks is removed; transferring pressure to the concrete, then duct is grouted to protect the tendons from corrosion.

SLAB BONDED POST-TENSIONING SYSTEM WITH FLAT DUCT (LIVE END SHOWING)

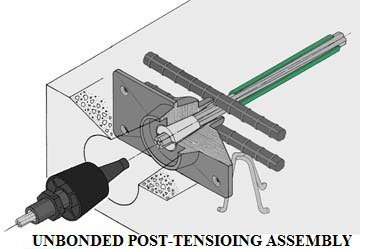

Un-bonded post-tensioned system varies from bonded post-tensioning system by providing each individual cable coated with grease (generally lithium based) and covered by a plastic sheathing, after concreting the stressing is processed.

"Cable can de-stress itself and burst out of the slab if damaged (such as during repair on the slab)"